Intelligent Production Line

Wind power concrete tower intelligent production line

01.

Wind power concrete tower pipe mold

Wind power concrete tower installation site

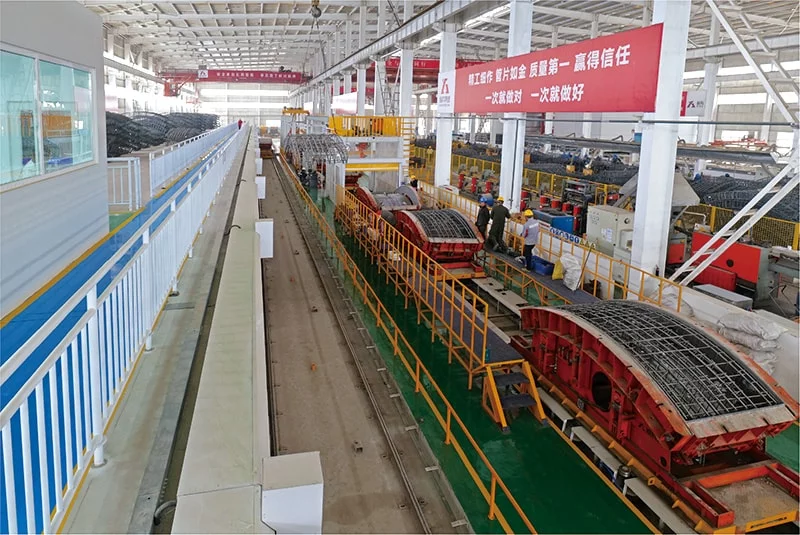

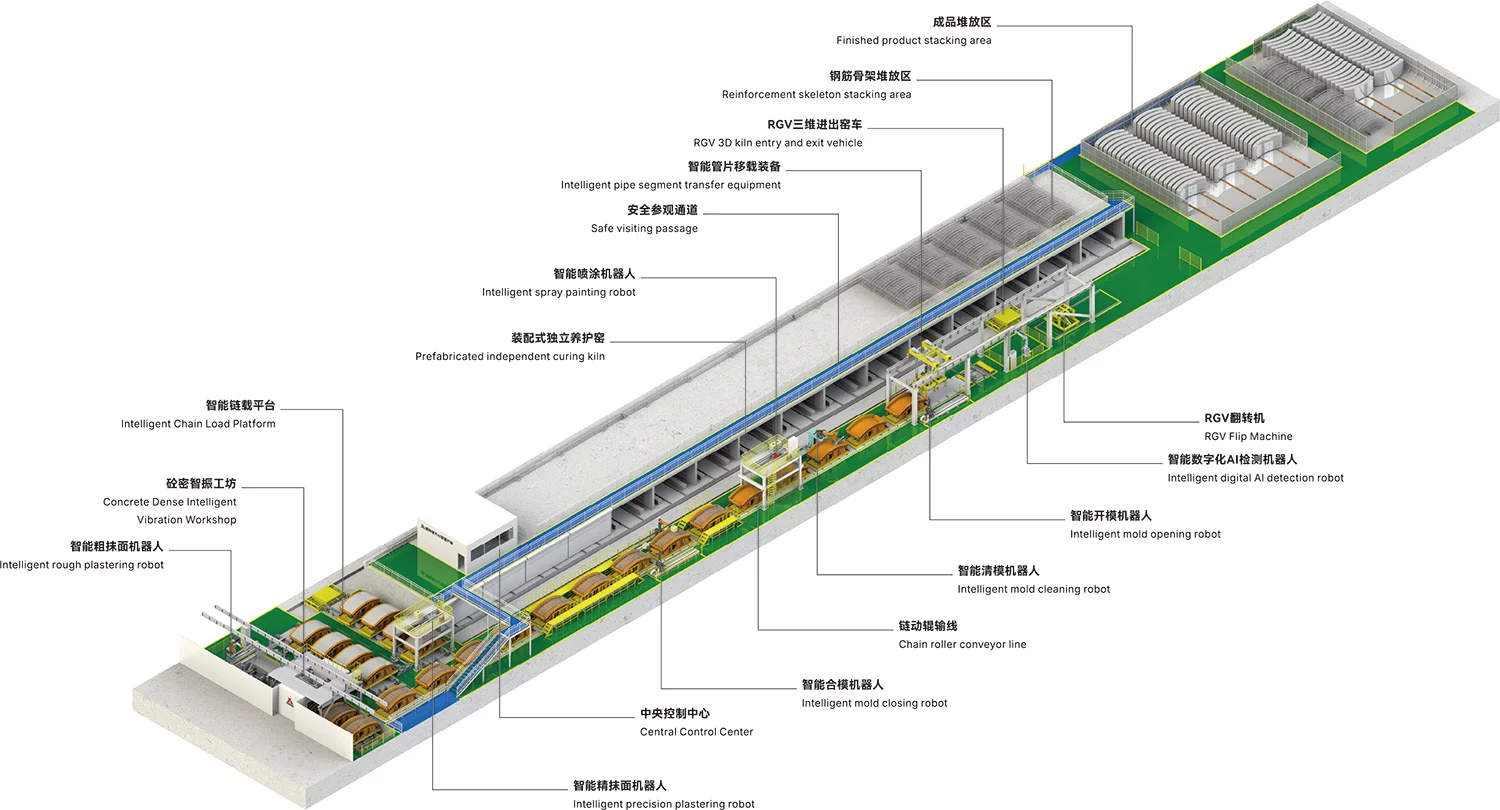

Shield tunnel segment intelligent production line

02.

After three years of independent R&D, Yugou Equipment has successfully built a domestically leading digital and intelligent production line for shield tunnel segments, breaking through multiple core technical bottlenecks and effectively addressing the development challenges of the industry. With "intelligent robots + AI technology" at its core, this production line has established an advanced horizontal-vertical integrated technical architecture:

Horizontally, it integrates artificial intelligence, robot clusters, digital twins, and MES (Manufacturing Execution System);

Vertically, it connects design simulation, intelligent manufacturing, quality traceability, and operation & maintenance services.

This integration enables full-process intelligent collaboration, accurately addresses customers' pain points, and significantly enhances their economic and social benefits.

The production line has developed a series of high-end intelligent equipment, including China’s first intelligent mold opening/closing robot for shield tunnel segments and AI-based digital inspection robots. These innovations make the production process more intelligent, efficient, and eco-friendly, while ensuring products are of higher quality, greater stability, and more comprehensive performance.

The core "Digital Intelligent Control Platform" deeply integrates the production control system, MES management system, digital twin system, and curing system, boasting prominent advantages such as "precise planning, controllable processes, on-site visibility, and traceable quality". Through virtual-real mapping and data integration, the platform realizes real-time full-scenario display and dynamic management of all links in the production line, covering the entire process of production, equipment, personnel, and products. This drives the transformation of on-site management toward digitalization, visualization, and intelligence.

The production line has achieved remarkable results in efficiency improvement, cost optimization, quality assurance, and energy conservation & emission reduction. Its technical achievements have passed authoritative industry certifications, making it a benchmark case in China’s intelligent manufacturing field. It provides a replicable intelligent solution for rail transit infrastructure construction and helps the industry step into a new stage of high-quality development.

Railway sleeper intelligent production line

03.

The production line features reasonable layout, small occupation area, smooth logistics and process connection, high degree of automation, stable product quality, and high labor efficiency. The instructions for process operations at each station are automatically controlled by the central control system, so that the randomness of operation is minimized and the process standardization is guaranteed. The tensioning, releasing and testing technology provides higher control accuracy, and maintains deformation pre-control with synchronization and uniformity.

Intelligent Double block rail sleeper production line

04.

Integrating digital simulation, intelligent robots, the Internet of Things (IoT), big data, and other technologies, the Intelligent Double-Block Production Line represents a major innovative achievement of Yugou Equipment. It actively responds to the national strategic development of intelligent construction, fosters new-quality productive forces, and deeply practices the concept of Industry 4.0.

① The production line integrates a variety of advanced workstations, including intelligent grinding, fully automatic installation of casing and spiral bars, fully automatic manufacturing and installation of truss bars, intelligent and precise material distribution and compaction, a fully automatic intelligent curing system, intelligent inspection and coding, and an unmanned palletizing system. It deeply interconnects production factors such as people, machines, materials, methods, and the environment (4M1E), and automatically completes production with almost no manual intervention—greatly improving production efficiency while reducing costs and energy consumption.

② The production line is equipped with Yugou’s Digital Intelligent Control Platform, an integrated system featuring intelligence, standardization, and informatization. Composed of DT (Digital Twin System), SCADA ( remote monitoring and control system for the production line), PHM (equipment fault monitoring system), and MES (information management system), this platform enables digitalization and traceability throughout the entire production process. With centralized management, it ensures the entire production process is green, energy-saving, safe, and highly efficient.

Intelligent production line of railway support block

05.

Bridge intelligent production line

06.

Based on the production mode of intelligent construction process and assembly line operation, the intelligent beam yard automation production line can automatically collect, analyze, and manage data using the"internet of Things+data analysis" technology, implement intelligent and automated operation of each process, and perform precise control of each prefabrication link, The production line features high logistics efficiency, safety and construction efficiency, as well as guaranteed professional procedures.

Originating From Prefabrication Learning More About Prefabrication

Phone: +86 0316-6171689

E-mail: [email protected]